AI for Accelerated Quotation Preparation in Maritime Supply Operations

AI system for marine supply quotations. Automatically matches requests with ERP data, retrieves pricing from history, and generates editable commercial proposals.

AI system development

3 AI developers

2 QA engineers

Maritime supply & ship chandling companies

Challenge

Long-distance maritime operations require reliable supplies of food, medicine, household items, and various types of equipment. A company specializing in provisioning vessels for extended voyages receives dozens of supply requests daily — covering a wide range of products.

These requests arrive in varying formats: PDF documents, Excel files, plain-text emails, itemized lists, or even hyperlinks. Buyers were manually entering product lines into the ERP system, checking against previous voyages, selecting suppliers and prices, and assembling commercial proposals.

In a highly competitive market with strict logistics constraints, this manual process led to significant time loss and a high risk of error. The client was seeking a technology-driven solution to shorten response times, reduce manual workload, and improve the accuracy of supplier matching. An AI-powered module became the answer.

Solution

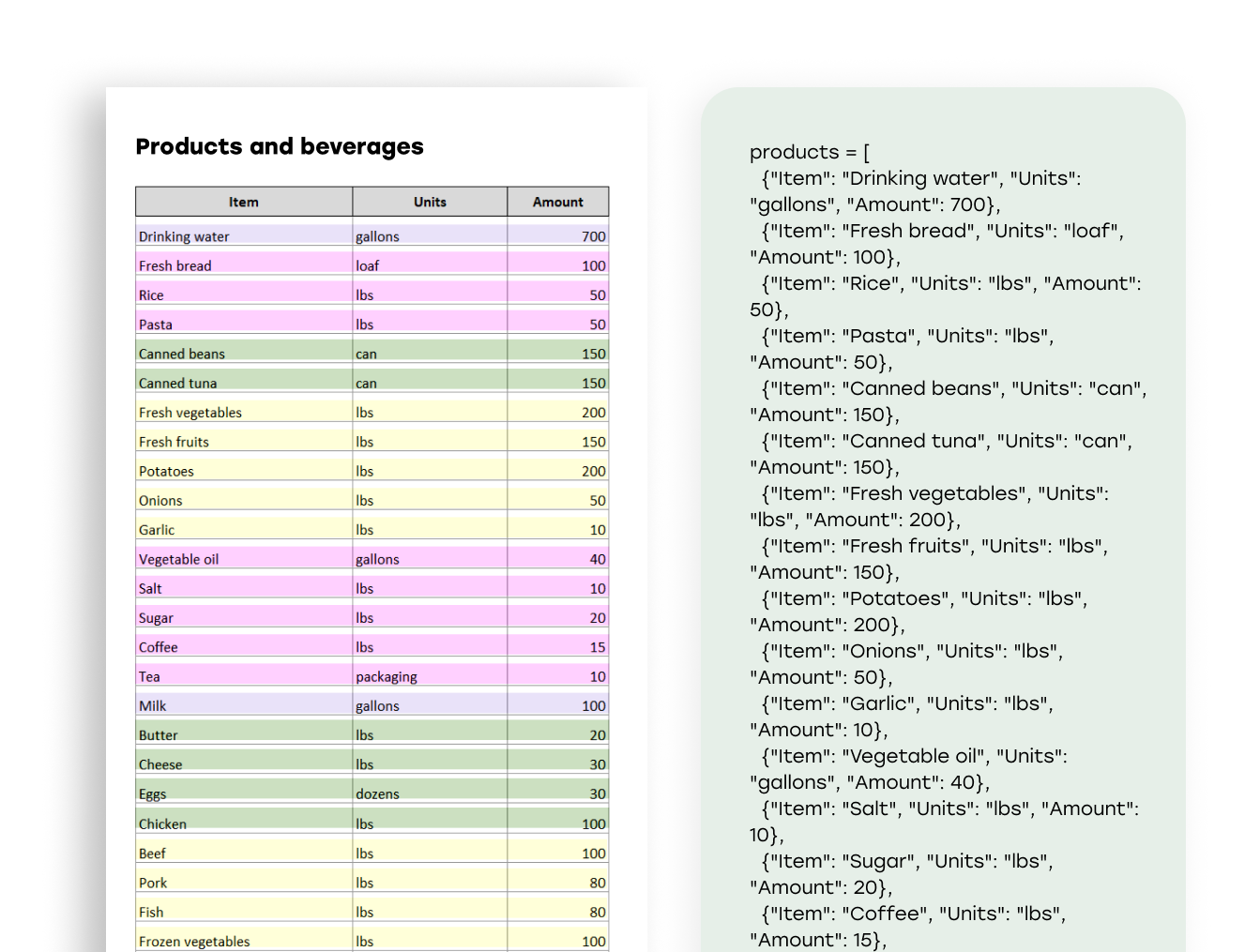

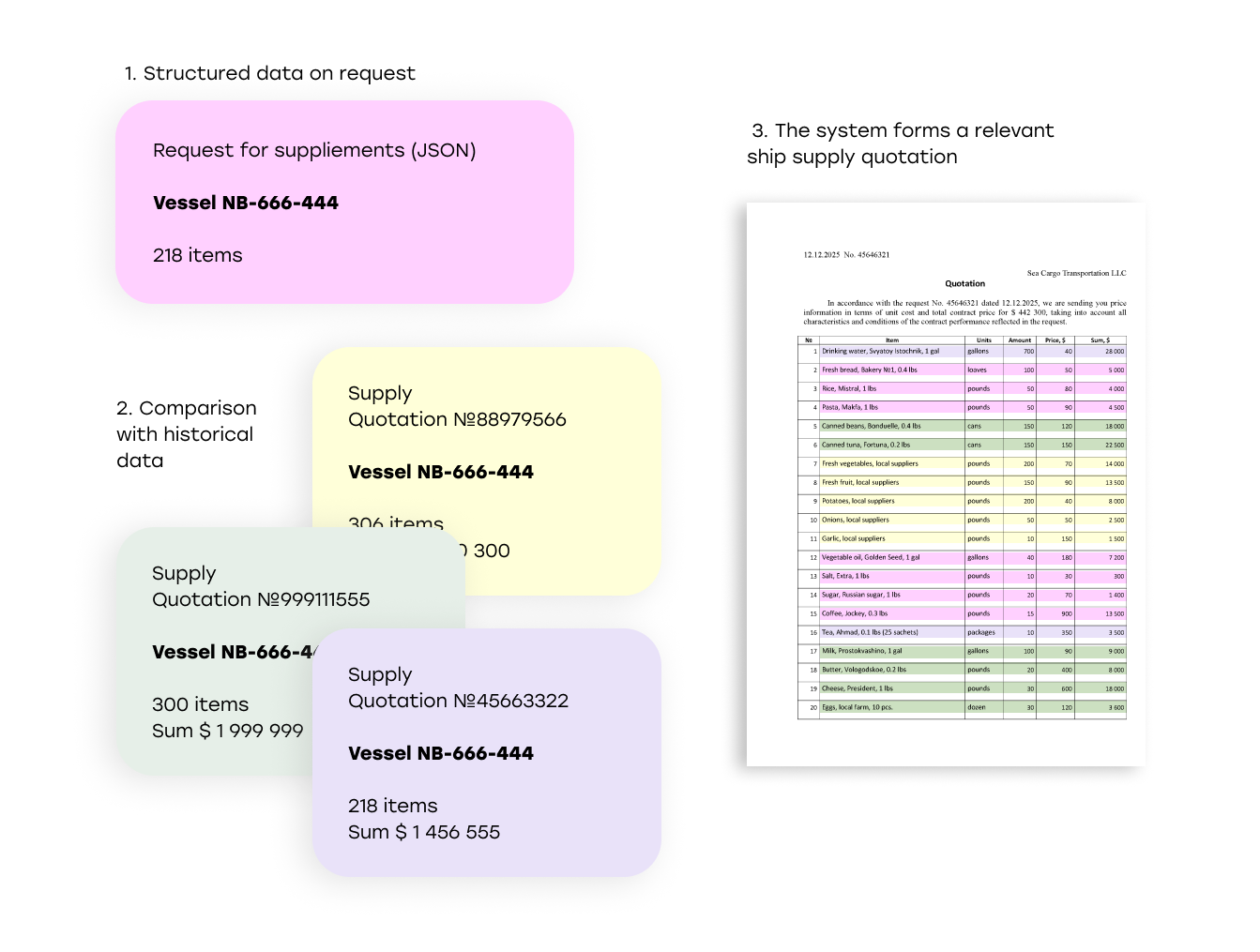

We developed an AI-powered module that automates the preparation of commercial proposals based on incoming requests. The system accepts unstructured documents in Excel, PDF, or plain-text formats. It extracts product lists through a multi-stage pipeline: using standard parsers and OCR first, followed by data normalization and classification.

Product Matching

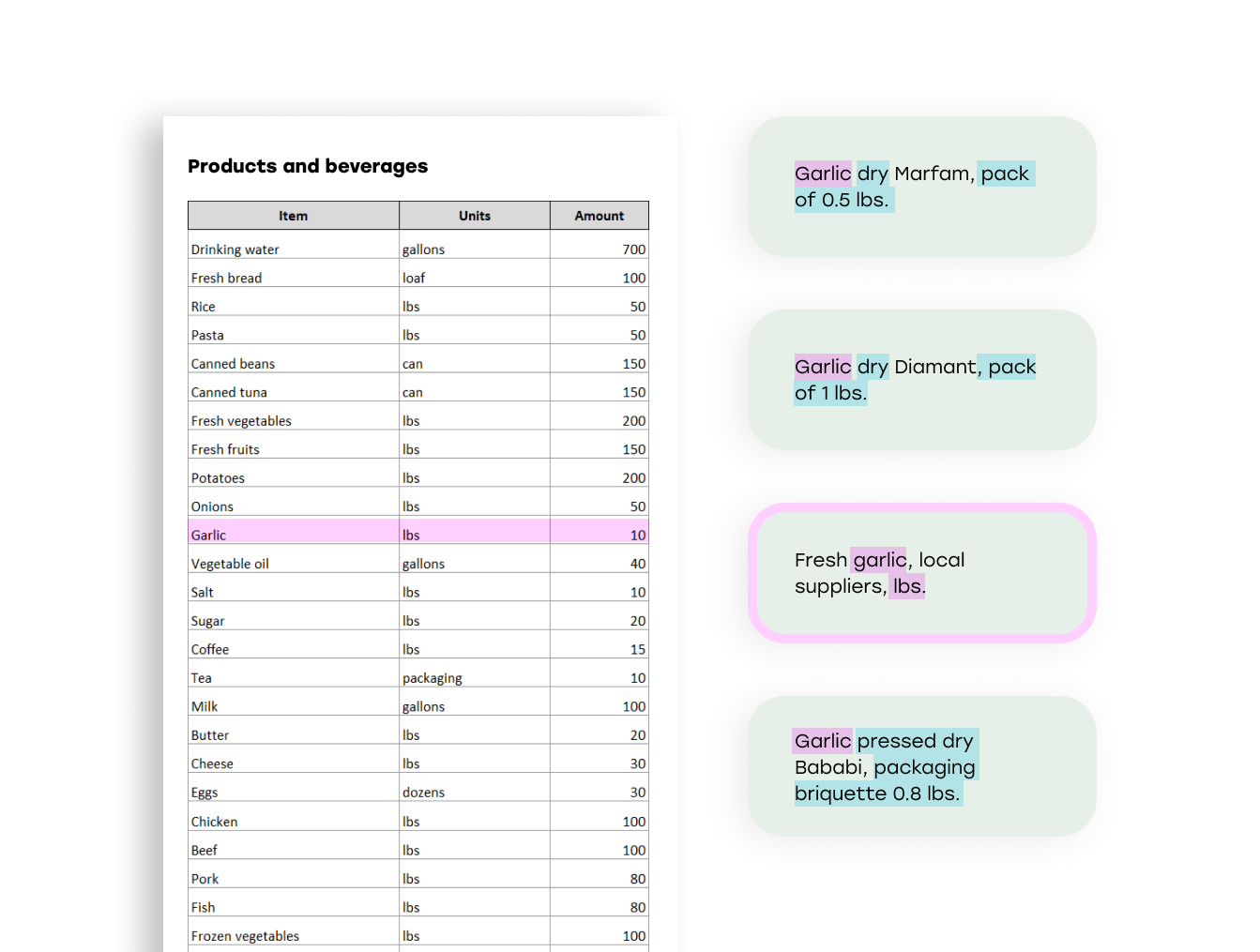

To identify matches between extracted items and the ERP product catalog, we used a hybrid approach combining vector search and fuzzy text matching. Technologies like FAISS and pgvector were used for embedding-based search, alongside cosine similarity and rapidfuzz for handling variations in spelling, inconsistent naming, or mixed-language inputs.

Proposal Generation

Once items are matched, the system selects the best available suppliers and prices based on the client’s purchasing history. Each recommendation includes a confidence score indicating how well the matched item corresponds to the original request. The final result is exported to an Excel file that buyers can review, adjust, import into the ERP system, and send to the client.

System Architecture

The solution was designed to be scalable: all components run in Docker containers deployed in Azure. The codebase is managed and deployed via GitLab CI. Initial ERP integration was handled through Excel exports, but the system is API-ready for future direct integration. The tech stack includes Python, FastAPI, PostgreSQL, and pgvector as the primary database.

Results

After implementation, the client gained a unified and manageable supply process across the entire fleet. Request processing time dropped from several days to just a few hours. Data normalization and automated validation reduced the number of errors and returns. Procurement managers appreciated the system's ease of use, while company headquarters gained real-time visibility into each vessel’s supply needs.

The platform proved effective in a fragmented infrastructure and is ready to scale to new business areas and partner companies. It has become a tool not only for automation but also for strategic resource management across the fleet.

Success Stories

Contact Us

Let's Work Together!

Do you want to know the total cost of development and realization of the project? Tell us about your requirements, our specialists will contact you as soon as possible.