Engineering Drawing AI Demo

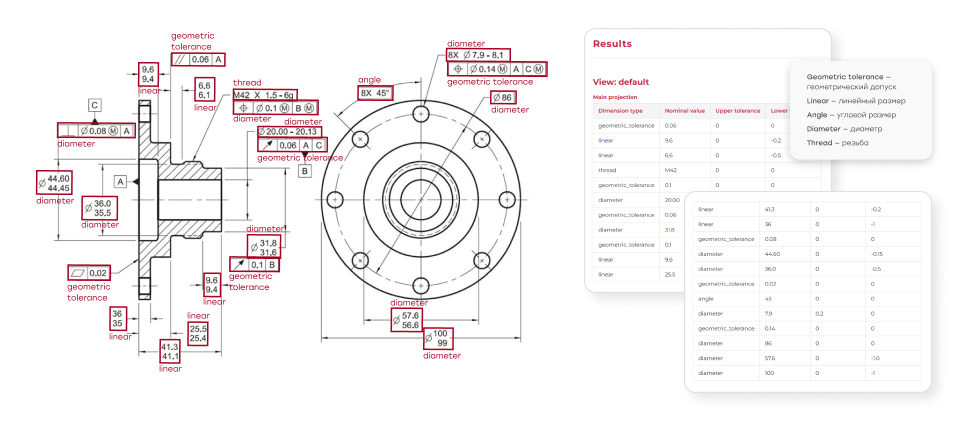

Upload real examples that defeat off-the-shelf solutions. See how a tailored AI model can extract dimensions and tolerances — usable for quality control and validation workflows.

Book a demo

this demo allows to:

Upload multi-page, messy, or detail-heavy drawings and stress-test the system.

- Works with rotated views and split sections

- Recovers information even from poor-quality scans

Test how accurately the AI identifies measurements, tolerances, and unit conventions across different standards.

Let’s talk about fine-tuning the model to follow your specific CAD conventions, drawing templates, and documentation workflows.

About This Demo

This is not a generic drawing parser. It’s a hands-on test environment designed to show how custom AI can handle complex engineering PDFs that standard tools often fail to process.

This demo is intended as a proof-of-concept sandbox: a safe space to experiment, evaluate, and imagine how a tailored AI solution could streamline your engineering drawing workflow.

Please note that our demo does not convert drawings from images into vector format. Additionally, this solution does not calculate the volumes of spaces, buildings, or rooms. Solving such tasks requires developing a custom drawing recognition solution.

How It Works

01

Upload Your Drawing

Works with both vector PDFs and scanned drawings.

02

AI-Powered Extraction

Our model reads dimensions and tolerances directly from the drawing.

03

Export to Your Workflow

Export extracted data as JSON or XLSX for further analysis or integration.

Test drive the AI on your most complex cases

Let's tailor this for your quality control pipeline, inspection and validation workflows

Book a demoFAQ

Yes. All uploaded files are handled in a secure environment and never used to train other models without your explicit consent. Private, on-premise testing can be arranged.

Yes — the demo is designed to show AI performance on messy, complex, or degraded drawings that boxed solutions often fail to read.

No — this is a testbed for evaluating a customizable AI model on your real-world drawings. The goal is to understand your needs before building a tailored solution.

Currently, the demo works only with PDF files (vector or scanned).

We can refine the AI on your data, increase accuracy for your formats, and discuss integration with your existing systems.

The data exported as JSON or XLSX can be directly applied to streamline inspection and quality workflows. Extracted dimensions and tolerances can populate checklists or templates used during manual measurements, allowing engineers to focus on verifying parts rather than transcribing values.

The same data can be used to automatically compare measured values against drawing specifications, highlighting any deviations and generating discrepancy reports.

Additionally, these structured outputs can be integrated into other tools or systems for analysis, tracking, or broader quality control processes.

No, it cannot. Our demo serves a different purpose.

Solving such tasks requires developing a custom solution, such as a drawing recognition system for a construction expertise bureau.

No, it cannot. Our demo serves a different purpose.

Solving such tasks requires developing a custom solution, such as a drawing recognition system for a construction expertise bureau.

Our demo is capable of:

Extracting tables and stamps, dimentions, Identify objects and present the detected objects in a tabular format.